-40%

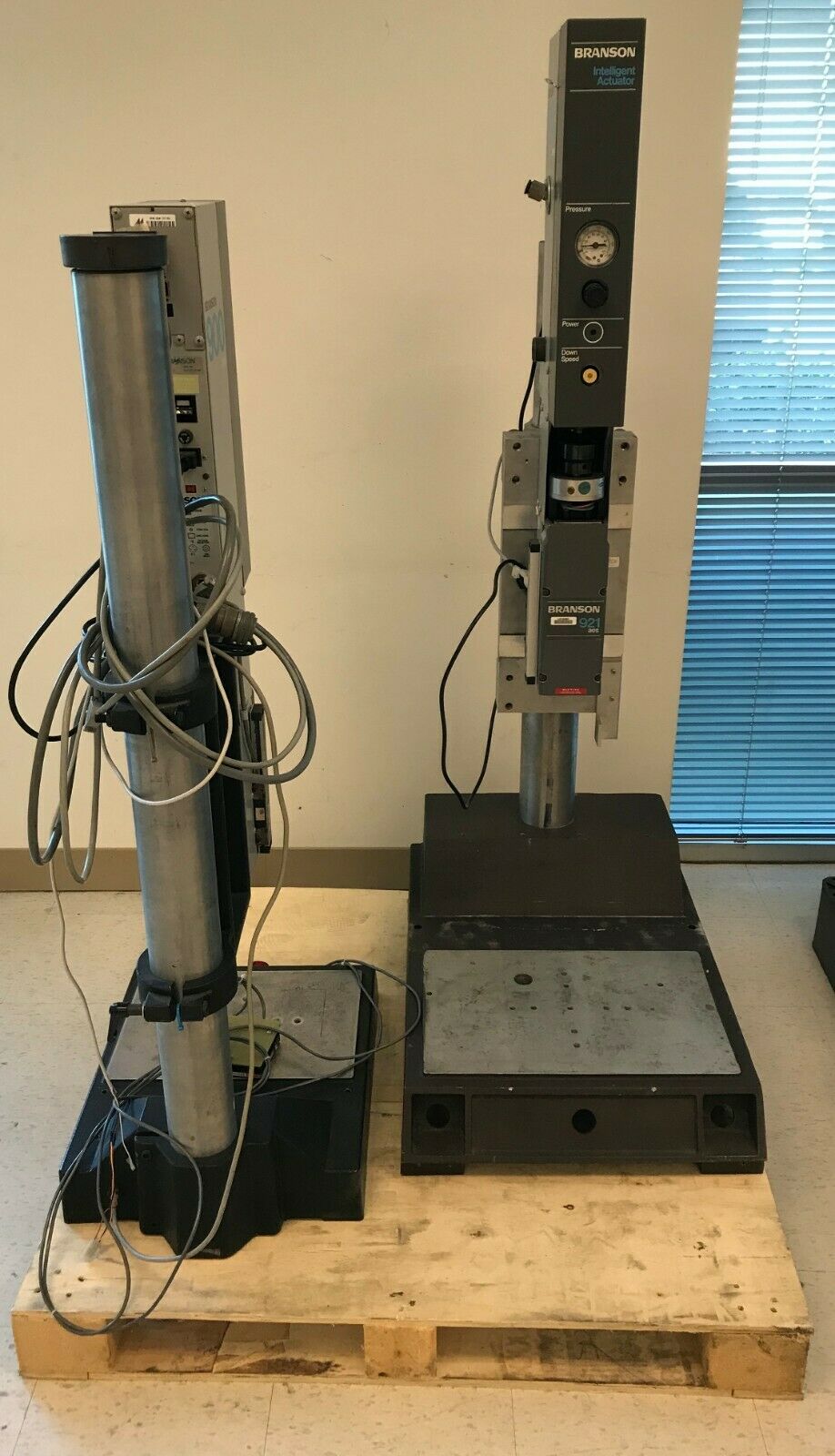

BRANSON 900 SERIES ULTRASONIC WELDER 921 AES FOR PARTS OR REFURBISHING

$ 1848

- Description

- Size Guide

Description

TWO BRANSON BRAND ULTRASONIC WELDERS AVAILABLE900 SERIES MODEL 921 AES

BOTH NEED REFURBISHING OR CAN BE USED FOR PARTS

LINEAR OPTICAL ENCODER - measures weld "distance" enabling welding by specific part collapse, to a finished part height, or until a ground detect device activates.

PRESSURE TRANSDUCER - accurately monitors air pressure, allows accurate and repeatable setting of weld pressure, and enables a digital display of gauge pressure on the power supply.

LOAD CELL (FORCE TRANSDUCER) - provides accurate Dynamic Trigger force with individually settable force window limits, return spring compensation, and enables the printout of a force graph for performance evaluation, monitoring, and recording.

DYNAMIC TRIGGERING - provides consistent weld quality by initiating (triggering) ultrasonic vibrations after a preset force, ranging from 10-200 lbs., is applied to the part.

DYNAMIC FOLLOW-THROUGH - as melting of the plastic occurs, dynamic follow-through ensures the smooth, efficient transmission of ultrasonic energy into the part by maintaining horn/part contact and force.

RUGGED CONSTRUCTION AND DURABILITY - rigidity and consistent, precise alignment of the horn and parts during welding is provided by linear ball bearing slides. The slide system incorporates linear motion guides with 4 sets of preloaded, permanently lubricated bearings. This design ensures long-term reliability, and allows smooth linear motion and well-balanced stiffness against loads applied from any direction.

EASE OF SETUP - converter/booster/horn stack installs easily and may be removed from the front of the carriage assembly without re-positioning the actuator. The stack may be rotated a full 360 degrees in the carriage for horn alignment with the workpiece.

VERSATILITY - The compact size allows close side-by-side stacking of the multiple actuators and facilitates the incorporation of the unit in automated and semi-automated production systems.

CONVERTER COOLING - cooling air is directed into the carriage to the top of the converter during each operation cycle

BUILT-IN ADJUSTABLE 24 TPI LOCKING MECHANICAL STOP - with an adjustment knob - when properly set, the stop prevents the horn from touching the fixture or nest when no workpiece is in place. It is internal to the carriage with only the adjustment knob exposed, allowing 360 degrees horn rotation without interference for alignment.

CARRIAGE HOME SWITCH - causes the power supply to produce a "ready" signal when the carriage has fully retracted. The ready signal can be used as a safety interlock switch on automated systems to prevent the movement of material handling equipment when the horn has not retracted. An optical switch provides reliable, wear-free operation.

AES ACTUATOR CONTROLS:

- flush-mounted 2" diameter pressure gauge provides excellent visibility for ease of setup; calibration is in both USCS and metric units

- precision regulator provides accuracy, control, and repeatability, with settings in 1 psi increments shown on the power supply VF display. Included is a locking feature that enables consistency of operation once the unit is set up

- calibrated flow control valve for downspeed gives accuracy, consistency, and repeatability machine to machine. A locking mechanism is built in.

- electronic pretriggering is provided by the 900M power supply; there is no mechanical switch to wear, adjust, or fail.

*****PLEASE NOTE:*****

Taxes are the responsibility of the Buyer.

All shipping/pickup is the responsibility of the Buyer.

In "AS-IS/WHERE-IS" condition. Available for inspection prior to purchase.

Available from Macrotron Systems